U.S.-China Trade War: Build A Supply Chain To Thrive In Any Trade Dispute

Businesses across the world are concerned about the climate of uncertainty that has clouded the outlook for global trade. Brexit is a big deal. But the U.S.-China trade conflict is a seismic event. Massive tariffs are being levied, markets are being closed, and the dialogue has not made any observable progress.

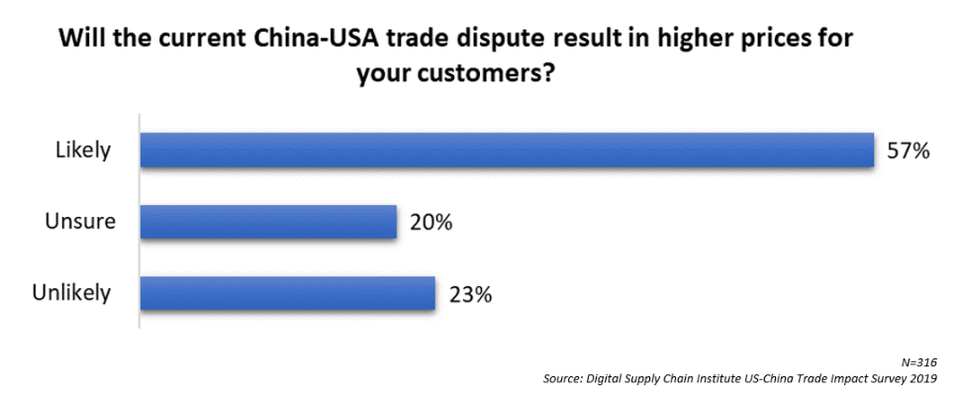

Most companies have a significant portion of their supply chain in China, either directly or through their suppliers. And almost all global companies view China and the U.S. as prime markets. The stakes are high. Companies are unsure of how the U.S.-China trade conflict will affect their sales and profit goals in China and the U.S. over the next three years. One outcome is likely: Consumers will pay higher prices.

Supply chain leaders are struggling to respond to this maelstrom of events. Many global companies are doing what they always do: redraw the geographic lines of their supply chains. According to a recent survey the Digital Supply Chain Institute (DSCI) conducted with over 200 leaders of global supply chains, 57% indicated that their companies are in the process of opening new locations for their supply chain outside of China.

Changing suppliers or moving plants is only a piece of the puzzle. A prerequisite for success in this trade-challenged environment is a Digital Supply Chain that takes a “nomadic sourcing” approach. Customer focused supply chains, automated processes, new manufacturing technology, strong AI-supported algorithms, and talented people will allow companies to change their sourcing locations more easily.

Here are five things that every company should do to thrive in an environment rife with trade disagreements, tariffs, closed markets, and all the associated business problems:

- Accept that trade issues will continue to impact the globe.

- Implement a Digital Supply Chain that requires a “Frontside Flip” from current processes to focus on customers. In other words, make sure that you make customers happy and deliver what they want when they want it.

- Adopt a plan for “nomadic sourcing.” Be agile enough to shift production as political and economic measures take effect. Nomadic sourcing means that you are willing and able to shift production to the lowest cost or highest value geographies.

- Decide how you will handle any short-term cost increases driven by tariffs or other issues. Will you pass them on to the customer?

- Determine how your Digital Supply Chain will become the very best for your customers. Make sure that you have the right complement of skilled people (especially people who make decisions based on data/analytics and analysis). I have not yet met a company that has all the right people, and all the right training. Many of you will be surprised by how much people change is required.

We conducted a major survey with companies across the globe and their responses are fascinating and foreshadow some major changes in the structure of world business. Go to our website and see the results.

Leave a Reply

Want to join the discussion?Feel free to contribute!